It has occurred to me in the intervening weeks that leaving this blog alone for a year might have actually been quite useful, because I’ve probably forgotten a whole bunch of stuff I would otherwise have shoehorned into this thing. Trying to explain Reynolds numbers… yikes. That took so long to write.

Thus, with a freshly-forgetful new start, we move on to the last post in our wing design series: the control surfaces.

What do they do? What are they called? Does absolute morality exist? What is the meaning of toast? Why are these questions going so far off-kilter?

We’ll cover the first two points now, and the other two… probably never.

For the first two questions: the moving parts are essentially there to control the lift being produced by the wing surfaces. If you can control the lift, you can control your flight.

This has two very important purposes:

Rolling

You need to change direction? Ailerons have you covered. By increasing the lift on one wing surface and decreasing it on the other, the aircraft will roll. This tends to be handy for making a turn. It works like so:

Lower the aileron on one wing, and that wing’s increased lift will cause the wing to rise. Raise the flap on one wing, and your lift will be reduced, causing the wing to fall. Combine a raised aileron on one wing with a lowered aileron on the other, and the effects will combine for double the fun.

Ailerons are mounted towards the wing tips, which gives them the greatest turning force – think of how it’s easiest to hold a seesaw down if you apply pressure at the end, rather than near the middle.

Flying really slowly without falling down and embarrassing yourself

Let’s say you’re sick of this whole flying thing and want to land. Problem is… you’re moving awfully fast compared to the ground. Go any slower and you’ll fall out of the sky, but land at this speed and you’ll risk some nasty scrapes.

Solution? Flaps!

Lower the flaps, and you get a whole whack of extra lift for an even bigger cost in increased drag. This makes flaps great for both landings and takeoffs – you can either kiss the ground at much kinder speeds, or take the extra lift and punch a hole in the sky by overcoming the drag with brute engine power.

There is also a third option, for when you really want to slow down fast. Flaps raise lift and drag, right? Well they have a counterpart: spoilers. Spoilers increase drag and decrease lift. Combine them with flaps, and you can stop moving and hit the deck extremely quickly – these are used more commonly on big airliners (which need a lot of ground room to slow down) and gliders (which have such efficient wings you have to actively disrupt them to be able to land comfortably)

However, we’ll be flying our inefficient, plank-like model fairly slowly and shouldn’t need these.

Fu…sion… Ha!

(I’m sorry, the quote seemed appropriate. In fact, I’m not even sorry. Sod off.)

But wait! Why have flaps and ailerons when you could have… flaperons?

Flaperons are fantastic, and are entirely as they sound – your flaps are ailerons, and your ailerons are flaps. They work by using a single length of control surface as an aileron, which (upon command) is deflected down slightly – you still have roll control, but with the added bonus of extra lift.

Flaperons are made possible by the wonderful magic programming of modern hobbyist radio systems, and are ridiculously easy to implement.

You can also reverse the mix and turn them into spoilerons, which are handy for model gliders. I used to use them on a powered glider, as it was just about the only thing which would make it want to stop flying – otherwise it would get to about 5 feet off the ground and ride a bubble of ground effect for the next hundred metres.

How Much Aileron?

Since we’ll be using flaperons, we won’t have to worry about taking flaps into account – we’ll just deflect the ailerons down a few degrees and ride the extra lift.

There are two important aspects to aileron design: how big they are, and how far they’re placed from the centre of our aircraft. Large ailerons will deflect more air, but moving them further along the wings will give them a greater lever effect. The seesaw analogy applies here – you can either have a large force tucked close in, or a small force further out.

It was at this point over a week ago that I decided we were going to design the ailerons with an aileron volume coefficient. Problem is, I can’t seem to find any sources on it. Does anyone actually use it? I honestly don’t know. Or I have forgotten, which is entirely possible. So I had to get rid of a whole block of text and maths which was very interesting and worthwhile and… oh, who am I kidding? It was too much, and it’s for the best that it’s gone. I quote from the discarded text:

“Great success! We’ve already reduced the entire bottom line down to an actual number.”

Yes, I typed that. Yes, this blog is supposed to be for non-engineers. And yes, I should really be sticking to something less tragically complex.

Thus: onward! To… whatever else we use to make this junk work.

In light of my horrible recent attempts at designing ailerons, let’s just do what all truly clueless people do: improvise copy someone else.

As far as I’ve seen, people tend to agree that pure ailerons (just used for rolling) should be 25% as long as your wingspan, and 25% the width of your wing chord, or 50% as long as your wingspan and 12.5% as wide as your wing chord.

Now, we want our ailerons to also serve as flaps. If we have short ailerons which suddenly start behaving as flaps, we’re going to have a whole extra heap of lift concentrated in a small section of the wings. Airflow doesn’t tend to like change, and these small but chunky flaps will present a big change in shape. This will generate lots of extra drag, and could cause unpredictable stall behaviour (which would be very bad indeed). We would be better served by long, thin flaps which distribute the extra lift evenly across the wing surface.

So, we’ll want ailerons 50% as long as our wingspan and 12.5% as wide as our wing chord, right? Well, those dimensions are all well and good for ailerons, but we’re going to be using flaperons. This is most easily explained in sequenced bullet points.

- Ailerons need to tilt up and down to maintain roll control during the flight

- Flaps only need to tilt down to generate the required extra lift

- Our flaperons have to operate as both ailerons and flaps

- Our surfaces only have a limited range of movement

- When dropping the flaperons for extra lift, some of this limited movement will be eaten into; the ailerons will not be able to move as far

- If our ailerons cannot move as far, we will have a reduced ability to control roll (aka “roll authority”)

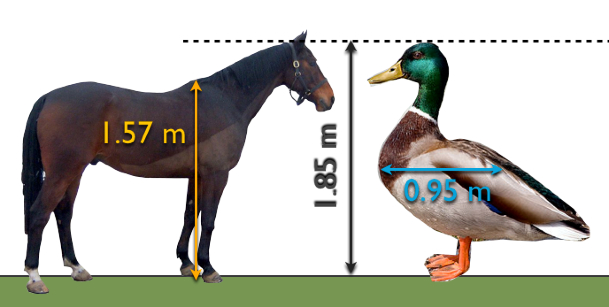

It’s like multitasking -trying to do two things at once will inherently make both things a bit worse than if you were trying to do them separately. Like trying to tie your shoelaces while playing the ukulele. Or trying to have a meaningful heart-to-heart conversation with someone while trying to fend off angry flocks of horse-sized ducks.

The solution? an open mind and some flamethrowers MOAR FLAPERONS.

To be more precise, we make our flaperons bigger so they can happily act as flaps without losing roll control. If there’s a drawback, it’s that we might have a bit too much roll authority when using the flaperons as plain ailerons (i.e. not dropping them for slow-speed flight). We can always compensate for this with our transmitter programming (this is massively easier than it sounds)

Because airflow is complicated and annoying, we’ll focus all of this extra size on the aileron chord length. We’ll boot in an extra 5%, which should give us a nice extra dose of surface area (span x chord) without going nuts. This means our ailerons will be 50% as long as the wing span and 17.5% as wide as the wing chord.

Little bit of maths here (rounded, because there’s no way we’re building to mm precision):

50% of 1.25m = 0.63m

17.5% of 0.27m = 0.05m

And because there are two flaperons (one for each wing):

Each flaperon will be 0.32m long, and 0.05m wide.

We want the flaperons as close to the wingtips as possible for extra roll authority, but we’ll sort out where exactly they can go once we get to proper modelling.

LET SUFFERING TAKE FLIGHT

You see, because it took so long to design wings, and wings… fly…

Well, those are the wings over and done with. It literally took me years, though arguably it should only have taken me a month or two if I had actually applied myself fully. I’m afraid we’ll only really be able to see the results of this particular post once we get the CAD (Computer Aided Design) work underway, which will be some time off.

So I guess we’ll cover the tail section next. In the meantime, I have a beer to finish and a risotto to reheat. Peace.